The Challenge

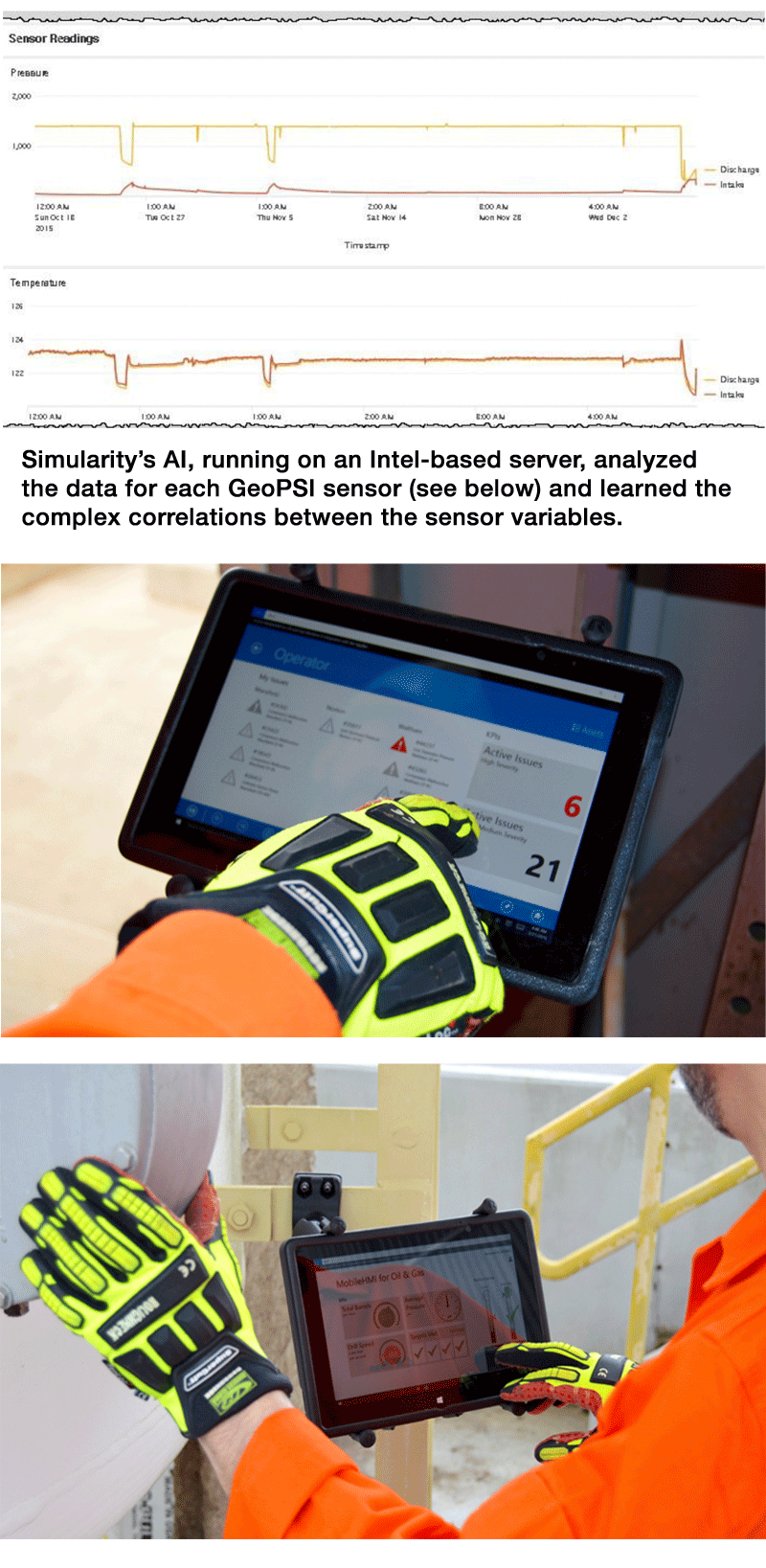

Using Real-Time Analytics, Downhole Sensor Data, and Hazardous Area Tablets & Sensors to Predict Failures and Confront “Time to Failure” in the Field Background Current market conditions in the Oil & Gas industry require greater efficiencies to remain competitive, and uptime is one of the most important KPIs for an organization’s sustained viability. When unplanned repairs or equipment replacement occurs, costing the organization two to three times more than planned maintenance and causing unexpected downtime, the inevitable question is, “what can we learn from this so that we can better anticipate in the future?” In the last decade, due to the hazardous (potentially combustible) nature of Oil & Gas environments that restrict the use of most computing devices, operational data was largely being reported on paper and clipboard, and none of this data was being used for maximum operational benefit. Now, with the integration of intrinsically safe sensors and mobile devices like tablets, organizations are beginning to connect “everything,” and use data from all component parts to form a better overall picture of an entire operation. With this insight, companies can use predictive analytics and artificial intelligence (AI) to better predict, plan and respond to anomalies, thus reducing cost and risk and improving overall safety and productivity. The Oman Incident: On December 9, 2015, at 4:56pm local time, a Progressive Cavity Pump (PCP) driven oil well in Oman known as “AV0902” suffered a break in the sucker rod string approximately 4700 feet below the surface. The unexpected shutdown required a completion workover service and replacement parts amounting to approximately $75,000. Industry average turn around for artificial lift repair is a week which also amounted to another 2,100 barrels of lost production. (At $40 per barrel = $84,000)