The Challenge

Introduction

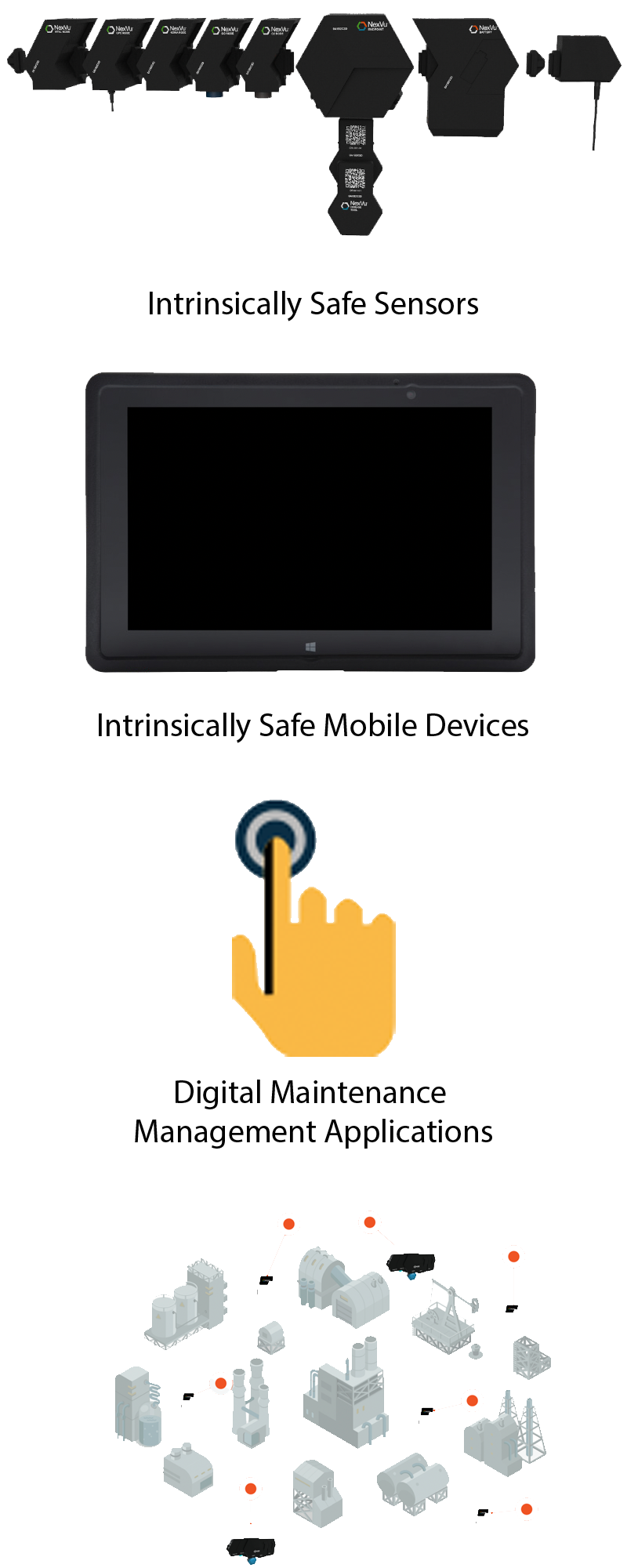

Proper maintenance is crucial for process manufacturing in industries with hazardous areas prone to explosions such as: oil and gas, chemical, pharmaceutical, and public safety. Maintenance is also a major contributor to the performance and profitability of a business. System failure can lead to costly stoppages in operation. Unplanned refinery shutdowns, for example, add cost to businesses with already tight margins. To effectively prevent breakdowns or accidents, operators must monitor all technical, administrative and managerial actions during the lifecycle of an asset. New technologies can help. Tools such as IoT sensors and mobile devices that are purpose-built for hazardous environments can monitor operations for potential problems and help prevent or reduce the impact of any issues. Preventive maintenance and asset performance management (APM) that is assisted by predictive technologies is designed to inspect assets while they work properly to reduce the likelihood of unexpected equipment failure. IoT technologies that can perform predictive maintenance without disrupting operations allow companies to better calculate when and how a critical asset may fail, and act accordingly to ensure the asset functions more efficiently and cost-effectively.The Problem

All refinery equipment deals with highly combustible materials and is located in Class I Division 1 hazardous areas where non-certified electronic devices are restricted due to risk of explosion. This restricts immediate access to data and communications while in the facility. Manual inspection of all assets is time-consuming, vulnerable to error in method or reporting, and delayed in the recording of data to ERP or other IT systems. Current sensors that monitor equipment function report individual silos of data about vibration, temperature, corrosion, pressure and other factors, but they are expensive and do not necessarily communicate with one another nor incorporate the data of other interdependent assets to provide a complete, real-time report of asset viability and performance. In the event of an abnormality, personnel working in the hazardous area hear alerts but cannot differentiate between a true emergency and a problem that could be solved with little risk, thus full stoppage of the operation is necessary to address the issue.