NexVu: The Aegex IoT Solution for Hazardous Locations

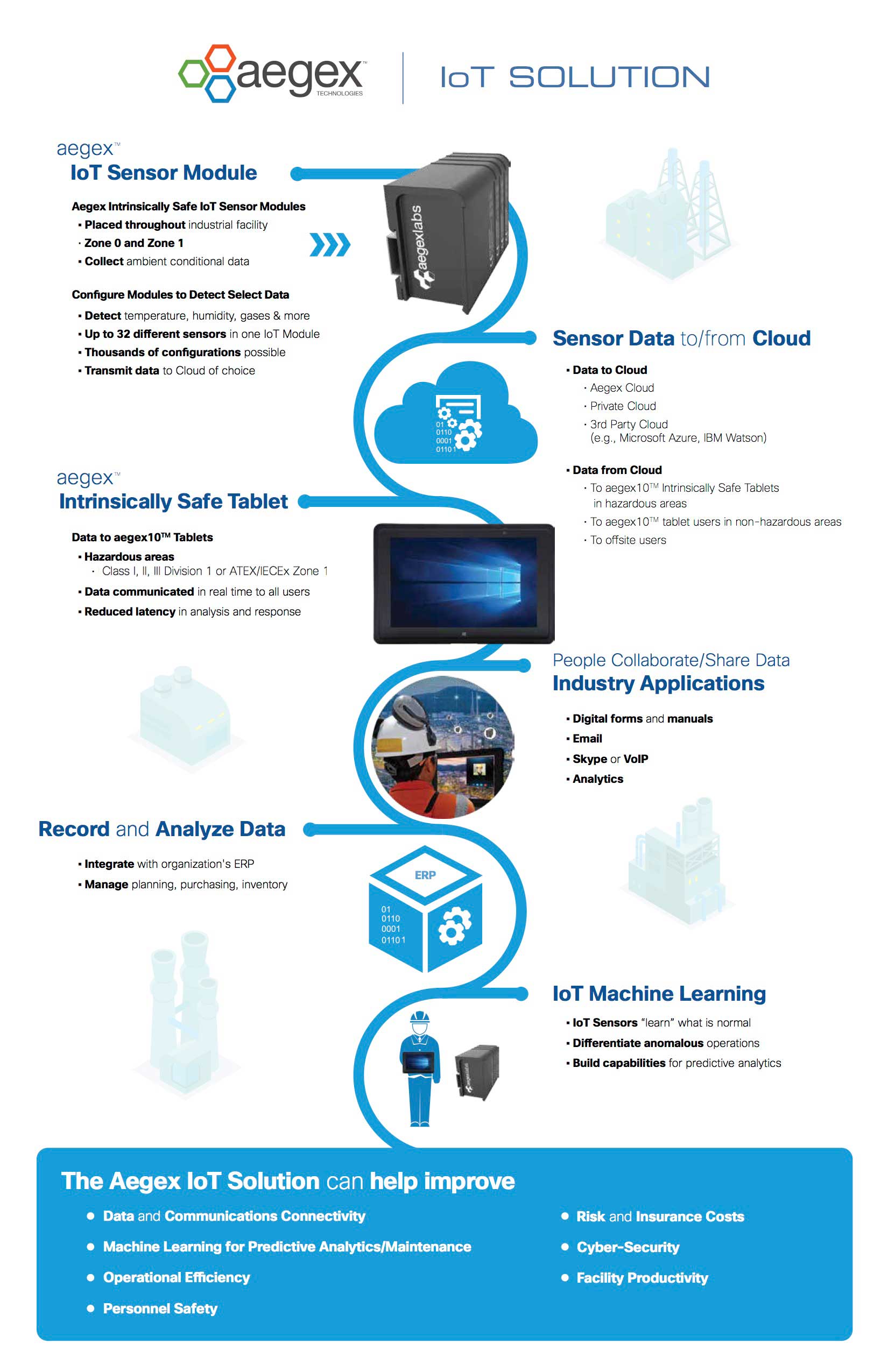

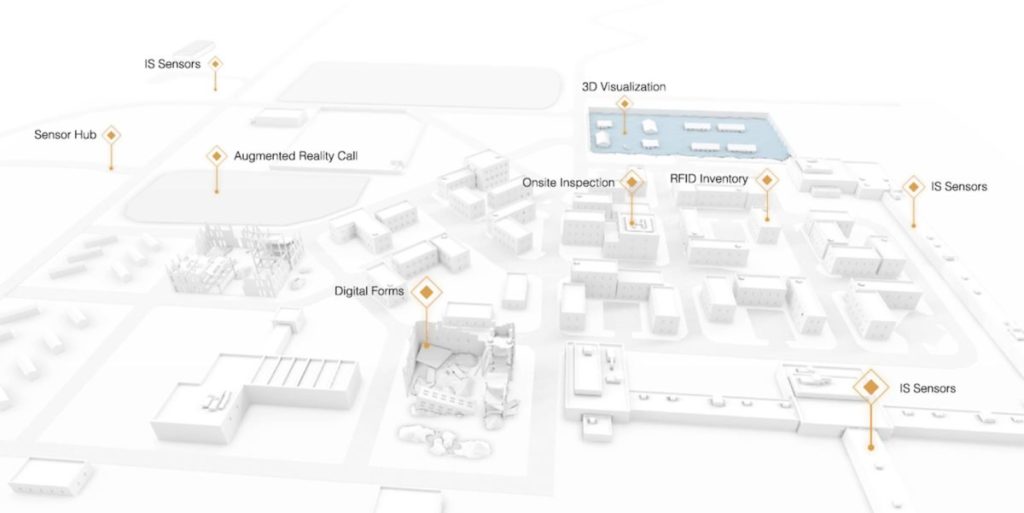

The Aegex NexVu IoT Solution for Hazardous Locations is comprised of various components that collectively gather, transmit, and analyze big data to efficiently and safely manage extremely large "meta-scale" operations, such as refineries or smart cities, where combustible atmospheres require highly regulated and certified equipment.

These elements working together form a comprehensive platform for enabling machine learning and artificial intelligence (AI) to manage Internet of Things operations in hazardous industrial locations in oil & gas, chemical, pharmaceutical and other potentially combustible environments.