aegex10TM Intrinsically Safe Tablet

The aegex10TM IS Tablet is purpose-built for use in the most hazardous zones of explosive environments.

READ MORE

Apps and APIs

Aegex offers a Windows-based platform that provides enterprise-class applications, security and customization.

READ MORE

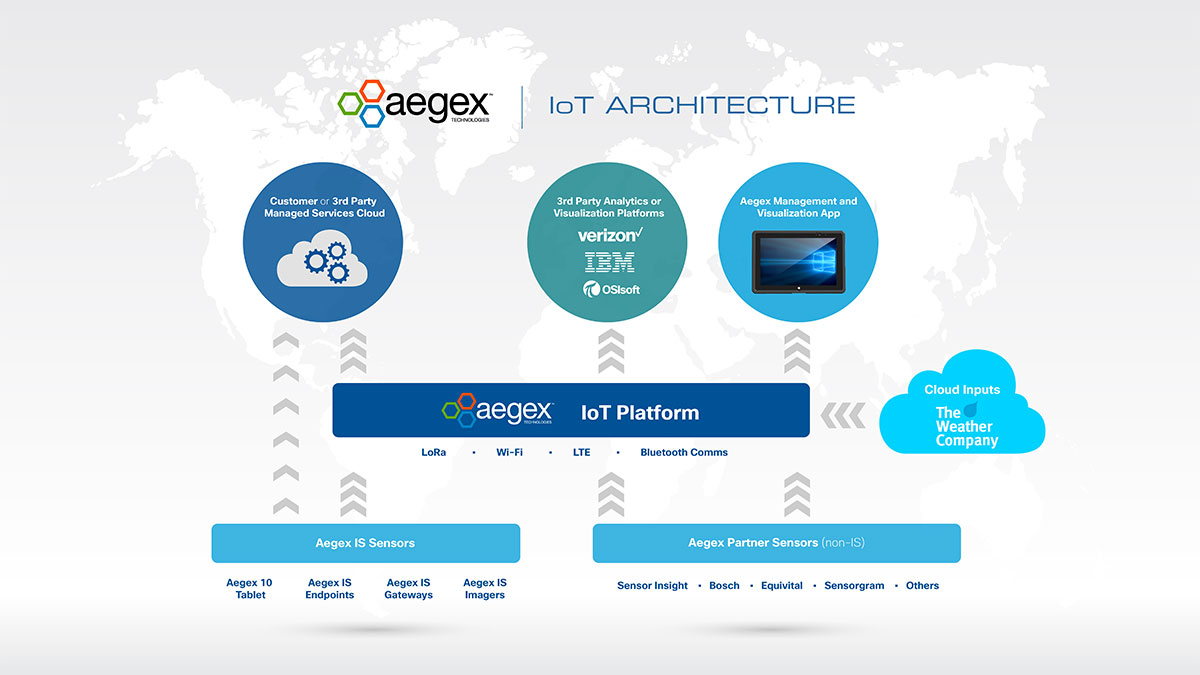

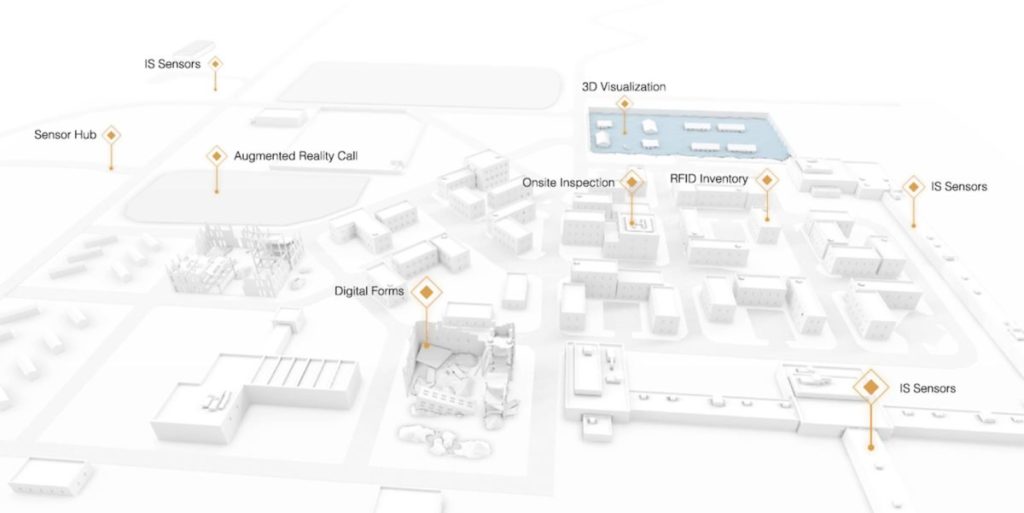

Intrinsically Safe IoT Sensors

The Aegex IoT Platform for Hazardous Locations is comprised of various components that collectively gather, transmit, and analyze big data to efficiently.

READ MORE

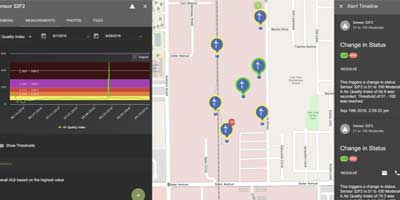

UI and Analytics

In environments where problems can quickly turn into catastrophes, the easy-to-read, real-time and accurate analysis of information can improve operations, protect the environment and save lives.

READ MORE